![]()

1. Flexible couplings transmit torque and rotational angle while absorbing misalignment. When the misalignment exceeds allowable values, vibration may result or the life of the coupling may become shortened, Make sure to adjust the alignment accordingly.

2. There are three types of shaft misalignment, namely in terms of paraltel misalignment, angular misalignment and shaft end-play . Adjust the alignment to be below allowable values listed in the specification table of each product provided in this catalog.

3.The maximum misalignment listed in this catalog is the allowable value when only one of the misalignments exists. ln case two or more misalignments exist at the same time, the allowable values will be less than 1/2 of the maximum misalignment listed in the specification tables.

4. Misalignments are sometimes caused not only by zequipment assembly, but also by vibration, heat expansion, wear of bearings, etc. during operation. Therefore, it is recommended to adjust the shaft misalignment to be below1/3 of maximum values.

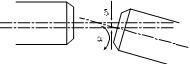

Parallel Offset Misalignment

During installation, when the two axes are parallel but the centerline is not in the same straight line, the deviation generated is called radial deviation. As shown in the right figure:

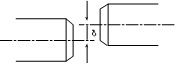

Symmetrical Angular Misaliqnment

During installation, the centerlines of the two shafts form an angle with each other, and the resulting deviation is called angular deviation, as shown in the figure on the right.

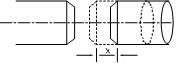

End-Play

The deviation of reciprocating micro movement between shafts due to mechanical reasons is called axial deviation. As shown in the right figure:

Combined Misalignment

The combination of deviations generated by 1, 2, and 3 is called composite deviation.