1 Introduction and Research Background

Couplings, as key components connecting two shafts or a shaft to rotating elements to transmit torque and motion, are indispensable in mechanical transmission systems. Long-span couplings, in particular, are essential for applications requiring connections over large distances, where their performance directly impacts the reliability, efficiency, and service life of the entire transmission system. As modern industrial equipment evolves toward high-speed, large-scale, and precision-driven systems, transmission systems face increasingly stringent requirements. Traditional metal couplings reveal limitations in long-span applications, such as excessive weight, low critical speed, and installation challenges.

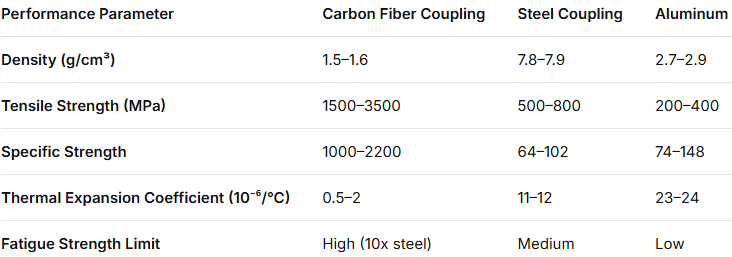

To address these issues, carbon fiber composites have been introduced into coupling manufacturing. Carbon fiber composites offer exceptional specific strength and specific modulus, along with design flexibility, providing new technical pathways for long-span coupling development. Their lightweight, fatigue resistance, and corrosion resistance meet the key technical demands of long-span couplings. Research data indicate that the tensile strength of carbon fiber composites can be 6–12 times that of ordinary steel, with a higher elastic modulus and a weight only about one-fifth of steel, making them significantly advantageous in long-span applications.

Diaphragm couplings, as a type of non-lubricated metallic flexible coupling, use metal diaphragms' elastic deformation to compensate for misalignment between connected shafts and are widely used in various mechanical transmission systems. Combining carbon fiber tubes with metal diaphragms in carbon fiber long-span diaphragm couplings retains the compensation capability of traditional diaphragm couplings while enhancing overall performance through material innovation. Such couplings are particularly suitable for high-temperature (-80 to 300°C), high-speed, and corrosive environments, demonstrating strong technical advantages in modern industrial transmission systems.

This paper analyzes the technical characteristics, harsh environment adaptability, and industry applications of carbon fiber long-span diaphragm couplings from an engineering perspective, providing selection references and application guidance through comparisons with traditional couplings.

2 Technical Characteristics of Carbon Fiber Long-Span Diaphragm Couplings

2.1 Material Properties and Structural Design

Carbon fiber long-span diaphragm couplings primarily consist of a carbon fiber composite tube and metal diaphragm groups. The carbon fiber tube serves as the main transmission shaft, transmitting torque and supporting rotation, while the metal diaphragms compensate for axial, radial, and angular misalignments. This hybrid design optimizes performance by leveraging the advantages of both materials.

Carbon fiber composites, composed of carbon fibers and a resin matrix, are manufactured through specialized layup and winding processes. Their specific strength (strength-to-density ratio) and specific modulus (modulus-to-density ratio) far exceed those of metallic materials, providing significant advantages in long-span applications. For example, reinforcing hard aluminum (LY-11Al) alloy tubes with carbon fiber wrapping enhances their transverse and axial load-bearing capacity. This reinforcement is particularly critical in long-span couplings, where greater length exacerbates sagging and deflection issues under rotation.

2.2 Lightweight Characteristics

The most notable advantage of carbon fiber long-span diaphragm couplings is their significant weight reduction. Compared to traditional steel shafts, carbon fiber shafts can reduce weight by approximately 70% (including necessary metal end fittings). This lightweighting offers multiple benefits: reduced inertia enables quicker start-stop cycles, ideal for frequent acceleration and deceleration; lower rotating mass decreases radial loads on supporting bearings, extending their service life; and reduced energy consumption, particularly in continuous operation equipment like fans and pumps, leads to notable energy savings.

Table 1: Performance Comparison of Carbon Fiber vs. Traditional Metal Couplings

2.3 High Critical Speed and Vibration Damping

In long-span transmission applications, critical speed is a crucial technical parameter. Resonance occurs when the rotational speed matches the system’s natural frequency, potentially leading to failure. Carbon fiber’s high specific modulus increases the natural frequency, thereby raising the critical speed. The lightweight nature and superior internal damping of carbon fiber reduce vibration and noise during rotation, making these couplings indispensable in high-speed precision transmission systems like aircraft engines and high-speed machine tools.

Carbon fiber couplings also exhibit excellent toughness. As an anisotropic material, carbon fiber composites offer damping characteristics 4–5 times higher than aluminum and 2–3 times higher than steel, effectively absorbing vibrational energy and reducing vibration transmission. This enhances overall system stability and reliability.

2.4 Installation and Maintenance Advantages

The installation of long-span couplings has always been challenging in engineering practice. Carbon fiber long-span diaphragm couplings, due to their light weight and compact structure, significantly ease installation. Specifically, designs with intermediate shafts allow disassembly without moving machinery, facilitating on-site installation and maintenance. Moreover, carbon fiber’s excellent corrosion resistance withstands acids, alkalis, salts, and atmospheric corrosion, requiring no regular maintenance. Its fatigue resistance is 10 times that of steel, with a service life exceeding 20 years.

In practical applications, carbon fiber couplings adopt integral molding of flanges and shaft tubes, surpassing traditional adhesive or riveted connections. This ensures high concentricity and stability, as the one-piece construction eliminates secondary connections, enhancing transmission accuracy. This design not only improves strength and service life but also prevents failures caused by loose or worn connections.

3 Industry Application Analysis

3.1 Aerospace Sector

In aerospace, transmission systems demand extreme lightweighting and high reliability, where carbon fiber long-span diaphragm couplings excel. In aircraft engines, helicopter rotors, and auxiliary power units, couplings must operate reliably at high speeds and temperatures while minimizing weight. Carbon fiber couplings weigh only 30% of traditional steel couplings, with high specific strength and specific modulus meeting stringent performance requirements.

In aircraft engines, carbon fiber long-span diaphragm couplings connect turbine shafts to generators, hydraulic pumps, and other accessories, transmitting substantial torque while compensating for thermal expansion-induced misalignment. Their high-temperature resistance ensures reliability in engine environments, while high critical speed guarantees stability at high rotations. Additionally, carbon fiber’s non-magnetic nature prevents interference with navigation systems, a crucial advantage in aviation.

3.2 Wind Power Industry

Wind power equipment, especially large MW-class turbines, requires highly reliable transmission systems. The connection between the main shaft and gearbox typically needs long-span couplings with good misalignment compensation and vibration damping. Carbon fiber long-span diaphragm couplings, with their lightweight, corrosion resistance, and fatigue resistance, are ideal for wind power systems.

In wind turbine applications, couplings endure varying wind loads and long-term alternating stresses, where traditional metal couplings are prone to fatigue failure. Carbon fiber composites’ fatigue resistance, over 10 times that of steel, resists damage from alternating loads, ensuring long-term reliability. The lightweight nature also reduces nacelle weight, benefiting overall structural design. Particularly in offshore wind farms, high-salinity, high-humidity corrosive environments pose challenges, which carbon fiber couplings’ corrosion resistance effectively addresses.

3.3 Petrochemical and Marine Engineering

Petrochemical industry equipment often operates in highly corrosive media and harsh conditions, such as pumps, compressors, and agitators. Carbon fiber long-span diaphragm couplings resist chemical corrosion and maintain stable performance in high-temperature, high-pressure environments, ensuring continuous and safe production.

In marine engineering, such as offshore drilling platforms and ship propulsion systems, couplings face high-salinity, high-humidity corrosive environments. Carbon fiber composites’ salt fog corrosion resistance makes them particularly suitable for marine applications. Their lightweight nature also reduces vessel and platform weight, improving load capacity and stability. In ship propulsion systems, long shafting often requires multiple support bearings; using carbon fiber long-span couplings can reduce the number of bearings, lowering system complexity and maintenance costs.

3.4 Other Industrial Sectors

Beyond the above, carbon fiber long-span diaphragm couplings are widely used in metallurgical machinery, mining machinery, printing machinery, and textile machinery. In these applications, couplings may face diverse challenges like high temperature, humidity, and dust, where carbon fiber couplings demonstrate excellent adaptability.

Particularly in high-speed, high-power transmission systems like turbines, generator sets, and high-speed pumps, the high critical speed and excellent dynamic balance of carbon fiber long-span diaphragm couplings ensure stability and reliability at high rotations. After dynamic balancing, they can operate at speeds exceeding 10,000 rpm, meeting stringent high-speed application requirements.

4 Application Technology and Comparative Analysis

4.1 Technical Comparison with Traditional Couplings

Carbon fiber long-span diaphragm couplings differ significantly from traditional couplings (e.g., gear, elastic sleeve pin, universal joints) in technical performance. Key parameter comparisons include:

In transmission efficiency, carbon fiber diaphragm couplings achieve up to 99.86%, thanks to no relative sliding and no need for lubrication, reducing frictional losses. Gear couplings, with meshing tooth sliding, typically have efficiency below 99.5% and require regular lubrication.

In compensation capability, diaphragm couplings accommodate twice the angular displacement of gear couplings, with lower radial reaction forces and greater flexibility, allowing axial, radial, and angular displacements. This enables reliable operation even with imperfect shaft alignment, reducing additional loads from misalignment.

In maintenance requirements, carbon fiber diaphragm couplings hold clear advantages. Unlike gear couplings, they have no relative sliding, need no lubrication or sealing, are quiet, and essentially maintenance-free. Gear couplings require periodic oil and seal changes, incurring higher maintenance costs.

4.2 Failure Modes and Solutions

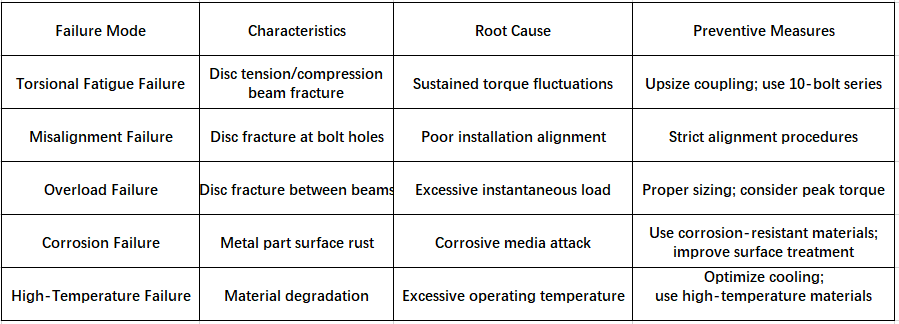

Carbon fiber long-span diaphragm couplings may encounter various failure risks in practice. Understanding these modes and implementing countermeasures is key to ensuring reliability. Common failure modes include:

Failure due to torque fluctuations. Torque variations subject diaphragms to alternating stresses, leading to fatigue fractures. For example, a compressor coupling failed after only 28 days due to torsional fatigue from sustained torque fluctuations. Solutions include identifying fluctuation sources, checking for load variations in drivers and driven equipment, upsizing the coupling, or switching to a 10-bolt series for higher diaphragm rigidity.

Failure from misalignment. Excessive installation misalignment introduces alternating stresses, causing diaphragm fractures near bolt holes. The solution is strict adherence to alignment specifications during installation.

Failure from overload. This typically manifests as diaphragm fractures midway between beams, due to instantaneous loads exceeding rated torque. Addressing this requires proper sizing during selection and informing manufacturers of actual operating conditions to ensure suitability.

*Table 3: Common Failure Modes and Preventive Measures for Carbon Fiber Long-Span Diaphragm Couplings*

4.3 Installation and Maintenance Technical Requirements

Proper installation and maintenance are crucial for reliable operation and long service life of carbon fiber long-span diaphragm couplings. Key considerations during installation include:

Precise alignment is fundamental. Use laser alignment tools to ensure shaft concentricity within allowable tolerances. Misalignment imposes unnecessary bending moments on diaphragms, shortening their life. Thermal expansion during operation should also be considered, adjusting alignment data accordingly.

Proper bolt pre-tightening is critical. Tighten connecting bolts to manufacturer-specified torques using a torque wrench. Incorrect preload affects diaphragm stress distribution, accelerating fatigue.

Clearance inspection is vital pre-installation. Check gaps between diaphragms and other components to avoid interference damaging diaphragms. For couplings with intermediate sections, ensure diaphragm groups are free from forced deformation.

Routine maintenance should include regular inspections of coupling condition: diaphragms for cracks/deformation, bolt tightness, and overall abnormal wear. Keep couplings clean, removing oil, dust, and contaminants, especially in corrosive environments. During operation, monitor vibration and temperature; abnormal fluctuations should prompt immediate shutdown and inspection.

5 Future Development Trends

Carbon fiber long-span diaphragm couplings, as high-end transmission components, evolve alongside advancements in materials science and manufacturing. Future trends include:

Intelligent monitoring technology will integrate sensors and monitoring systems to collect real-time data on torque, vibration, and temperature, enabling online health monitoring and fault prediction. This predictive maintenance approach enhances reliability and service life, reducing unplanned downtime.

Material innovations will expand performance boundaries. Developments like carbon nanotube-reinforced composites and self-healing materials will improve mechanical properties, environmental adaptability, and service life. Multifunctional composites could enable couplings to transmit torque while providing vibration damping and self-sensing capabilities.

Structural optimization combined with advanced manufacturing will refine coupling performance. Algorithm-driven topology optimization and generative design can create lighter, higher-performance structures. Automated manufacturing like robotic fiber placement and resin transfer molding (RTM) will enhance precision and consistency while reducing costs.

Multifunctional integration is another key direction. Future carbon fiber couplings may combine transmission, braking, and clutching functions, simplifying and optimizing transmission systems. Research on carbon fiber-reinforced lithium-ion battery composites demonstrates feasibility in integrating energy storage with structural functions, a concept applicable to smart couplings with combined transmission and energy harvesting capabilities.

6 Conclusion

Carbon fiber long-span diaphragm couplings, as high-performance transmission components, demonstrate broad application prospects in aerospace, wind power, petrochemicals, and other high-end equipment sectors due to their lightweight, corrosion resistance, and fatigue resistance. Through systematic analysis of their technical characteristics, environmental adaptability, and applications, the following conclusions are drawn:

The lightweight nature of carbon fiber long-span diaphragm couplings significantly reduces transmission system weight, lowers rotational inertia, improves system response, and decreases structural loads, offering an effective path for energy savings. Their high specific strength and specific modulus enable higher critical speeds, suitable for high-speed transmission.

In harsh environments, carbon fiber long-span diaphragm couplings demonstrate exceptional performance, resisting high/low temperatures, corrosion, dust, and other severe conditions, ensuring transmission system reliability. Their fatigue resistance is over 10 times that of ordinary steel, with a service life exceeding 20 years, significantly reducing lifecycle costs.

With advancements in materials science, manufacturing, and smart monitoring, carbon fiber long-span diaphragm couplings will evolve toward lighter, smarter, and more integrated multi-functional solutions, providing comprehensive transmission answers for modern industrial equipment. Engineers should select and design couplings based on specific application needs to fully leverage their technical advantages and drive technological progress in equipment manufacturing.