Misalignment and unbalance are among the most common faults in rotating machinery. When misalignment or unbalance exceeds a certain level, it can worsen vibrations, accelerate bearing wear, reduce equipment lifespan, and compromise safe and stable operation. In practice, these issues can be quickly identified through vibration characteristics.

I. Misalignment

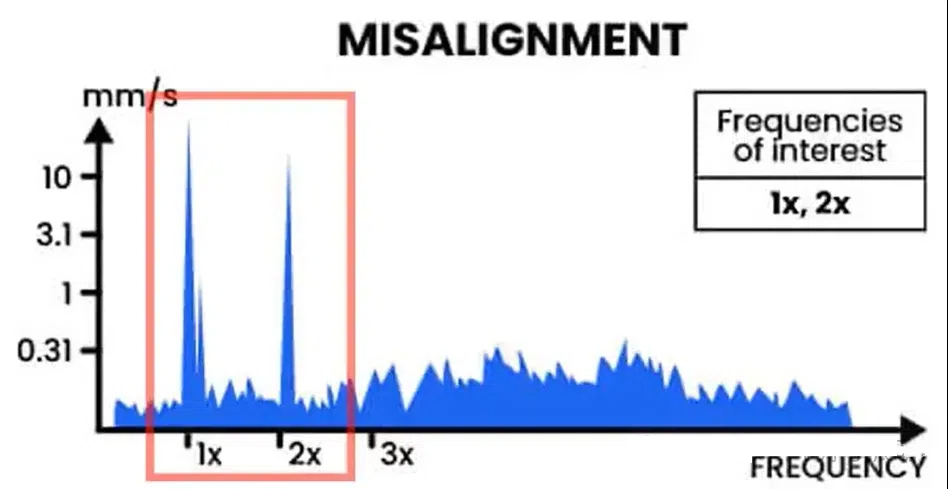

Based on the direction and form of shaft centerline deviation, misalignment is mainly classified into the following three types. In practice, these often occur in combination.

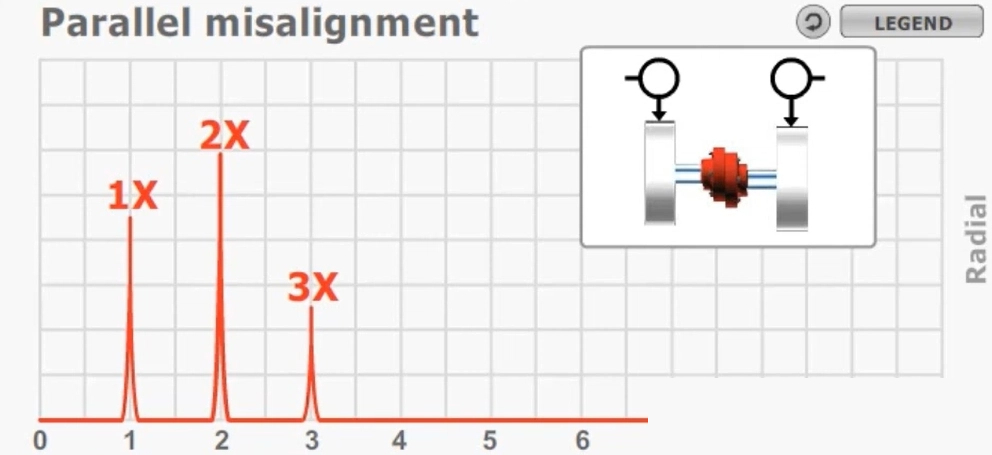

(1) Parallel Misalignment

The centerlines of two rotors are parallel but not coaxial, resulting in a radial offset. This is mainly caused by improper coupling alignment during installation, bearing wear leading to shaft sinking, or uneven foundation settlement.

Typical characteristics: Presence of 1x, 2x, 3x frequencies, with a prominent 2x frequency. Sometimes 4x and 5x frequencies may also appear. A 180° radial phase difference is observed on both sides of the coupling.

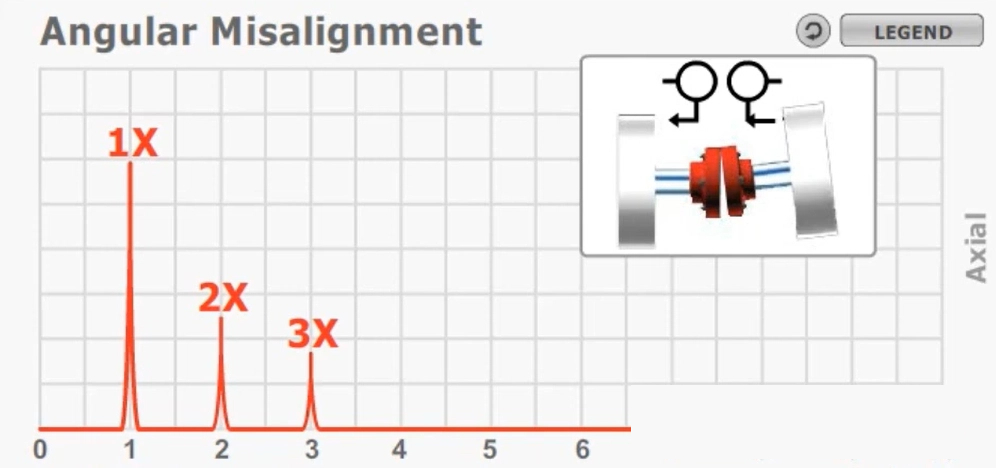

(2) Angular Misalignment

The centerlines of two rotors intersect but are not parallel, forming an angle. In engineering, this can result from uneven tightening of motor or pump anchor bolts, differential thermal expansion of rotors (e.g., in steam turbines), or bearing housing deformation.

Typical characteristics:** Presence of 1x, 2x, and 3x frequencies. A 180° axial phase difference is observed on both sides of the coupling.

(3) Combined Misalignment

This involves both parallel and angular misalignment and is the most common type in industrial applications. Most misalignment issues in rotating machinery, such as in centrifugal pumps, compressors, fans, and turbo-generators, fall into this category.

Typical characteristics: A combination of fault features from both parallel and angular misalignment. The spectrum shows 1x, 2x, and 3x frequencies, with significant radial and axial phase deviations on both sides of the coupling.

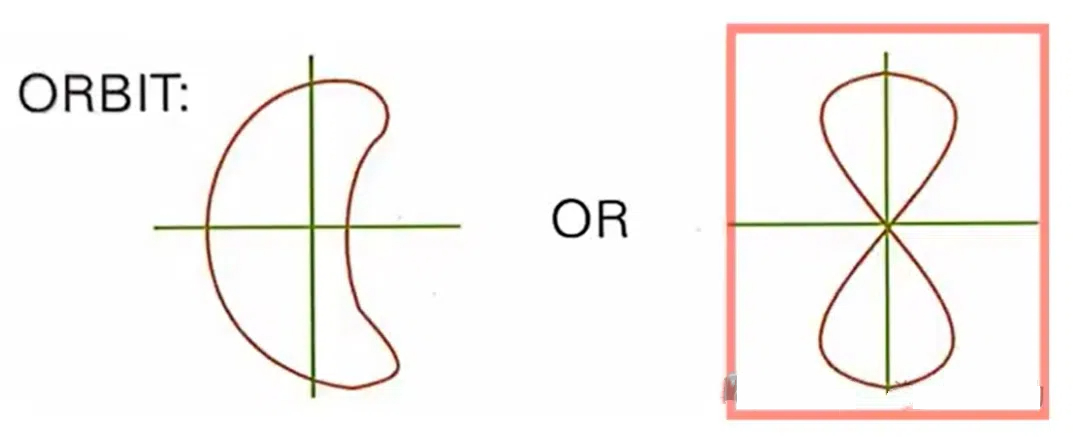

For steam turbine rotors equipped with shaft vibration sensors, further analysis of shaft centerline trajectory can be conducted, revealing characteristic patterns such as "figure-8" or "banana" shapes.

II. Unbalance

(1) Static Unbalance

Typical characteristics:Vibration is primarily radial at 1x frequency, with no significant axial vibration. The phase at both ends of the rotor is nearly identical. Vibration amplitude increases with rotational speed (proportional to the square of the speed).

(2) Couple Unbalance

Typical characteristics: Vibration remains primarily radial at 1x frequency, but a significant phase difference (typically around 180°) is observed in the radial vibration between the two ends of the rotor.

(3) Dynamic Unbalance

Typical characteristics: Vibration is dominated by radial components at 1x frequency, with possible minor axial vibration due to couple effects. The phase difference in radial vibration between the two ends of the rotor ranges between 0° and 180°.