1. Introduction

Within the broad spectrum of industrial power transmission, for the vast range of applications with power below several hundred kilowatts and operating at medium to high speeds (e.g., fans, pumps, compressors, conveyors, servo systems), drive designers consistently seek coupling solutions that offer the optimal balance between performance, reliability, and cost. The curved jaw elastic coupling, particularly its steel version, is an outstanding response to this demand.

It does not pursue extreme performance parameters (such as absolute zero backlash or ultra-high torsional stiffness) but instead provides a "good enough" and highly reliable solution through a clever and robust design. Its core design philosophy lies in utilizing the meshing of precisely calculated metal jaws with a high-performance engineering elastomer (spider) to achieve efficient torque transmission, while leveraging the deformation of the elastomer to absorb vibration, shock, and compensate for inevitable installation errors. This paper will deconstruct the technical core of this coupling type and define the boundaries of its engineering application.

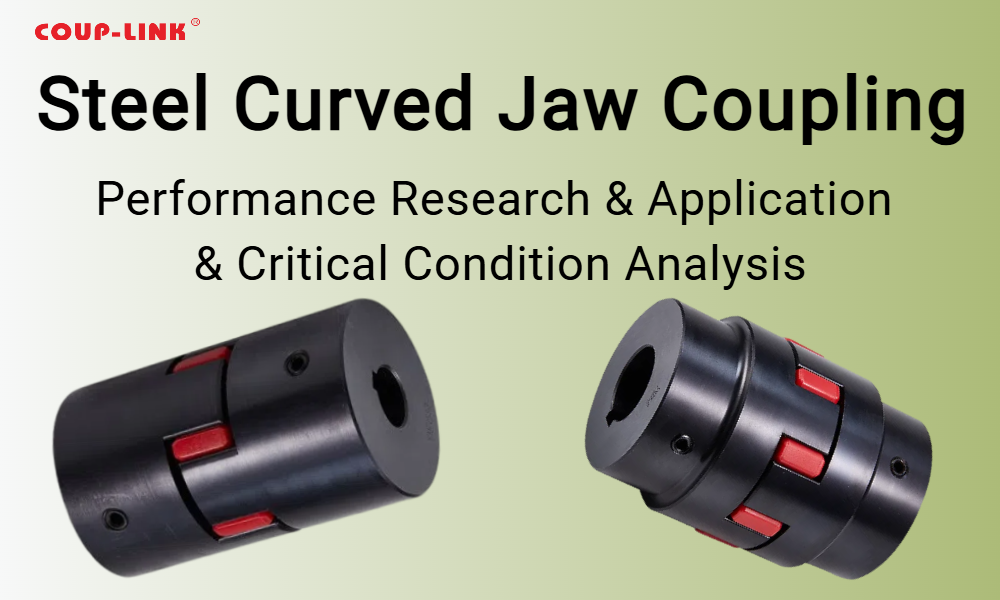

2. Structure and Working Principle

2.1 Basic Structure

A complete steel curved jaw coupling consists of three core components:

Two Steel Hubs: Typically made from high-quality alloy steel through forging and precision machining, offering high strength and fatigue life. Their outer rims are machined with continuous multi-lobe curved protrusions (the "curved jaws").

One Spider / Elastomer Element: The core functional component, usually made from materials like Polyurethane (PU), Hytrel (TPC-ET), or Nitrile Butadiene Rubber (NBR). Its shape perfectly meshes with the hub jaws, often hexagonal, octagonal, or decagonal.

2.2 Working Principle

The torque transmission path is: Driving hub jaws → Compress elastomer → Elastomer deforms → Driven hub jaws. The process essentially transmits torque through the combined shear and compression deformation of the elastomer.

Torque Transmission: Under rated torque, the elastomer deforms within its designed range, transmitting power efficiently.

Vibration and Shock Absorption: The high internal damping properties of the elastomer effectively attenuate torsional vibration and shock loads originating from the motor or load side.

Misalignment Compensation: The deformability of the elastomer allows it to compensate for certain amounts of axial (via elastomer compression), radial, and angular misalignment (via uneven elastomer deformation).

3. Core Advantages and Technical Superiority

High Torque Density and Compactness: The multi-lobe simultaneous contact design provides a large contact area, enabling high torque transmission in a relatively small package size, making the structure very compact.

Excellent Cushioning and Damping Performance: The elastomer element effectively absorbs and isolates high-frequency vibrations and instantaneous shocks, protecting equipment upstream and downstream in the drive train and reducing system NVH (Noise, Vibration, and Harshness).

Ease of Maintenance and "Fail-Safe" Mode: The elastomer is a standardized replacement part. When worn or damaged, only the spider needs replacement, without moving the connected equipment, resulting in very low maintenance costs. Under extreme overload conditions, the elastomer will shear and fail first, disconnecting the power transmission and acting as an overload protection device, preventing damage to more expensive equipment.

Electrical Insulation: Elastomer materials are good insulators, effectively blocking harmful shaft currents and preventing electrical erosion damage to bearings.

Excellent Cost-Effectiveness: Within its applicable power and operational range, it offers an unparalleled combination of reliability and cost advantage.

4. Application Fields

The jaw coupling is a true "industrial workhorse," widely used in:

General Material Handling: Belt conveyors, chain conveyors, screw conveyor drives.

Fluid Machinery: Drive connections for centrifugal pumps, fans, compressors.

Small and Medium Servo and Stepper Systems: Precision positioning applications requiring some flexibility and damping.

Agricultural Machinery, Food Processing Machinery, Packaging Machinery, and other environments with complex conditions or requiring frequent cleaning (food-grade elastomer materials available).

5. Critical Condition Analysis and Usage Considerations (Key Engineering Practices)

5.1 Elastomer Performance Degradation and Selection

Material Properties: The elastomer's performance is core. Polyurethane (PU) offers high hardness, wear resistance, and high torque capacity but poor low-temperature performance; Nitrile Rubber (NBR) has good oil resistance; Hytrel offers better high-temperature and fatigue performance. The correct elastomer material must be selected based on ambient temperature and media compatibility (oil, ozone, chemicals).

Thermal Aging and Power Loss: Under continuous alternating stress, the elastomer generates heat due to internal friction. If the heat generation rate exceeds the dissipation rate, the elastomer temperature will rise continuously, leading to material softening, strength reduction, accelerated aging, or even melting failure. The allowable short-term and long-term operating temperatures of the coupling must be verified.

Creep and Backlash: Under sustained torque, the elastomer undergoes slow plastic deformation (creep), leading to a reduction in pre-compression force and resulting in backlash during reversal or start-stop cycles. This is unacceptable for high-precision positioning applications. Select harder, more creep-resistant materials (e.g., Hytrel) for such uses and perform regular inspections.

5.2 Impact and Limitations of Misalignment

Although capable of compensating for misalignment, any form of misalignment significantly shortens the elastomer's service life. Angular and radial misalignment create cyclic additional stresses within the elastomer, accelerating its fatigue failure. Misalignment must be strictly controlled within 50% of the values allowed in the product catalog, and optimal alignment should be pursued whenever possible.

5.3 Installation and Maintenance Specifications

Hammering Strictly Prohibited: Special installation tools or threaded rods should be used for mounting. Directly hammering any part of the coupling is absolutely forbidden to avoid damage to the jaws or bearings.

Axial Clearance: A specified axial gap must be maintained between the two hubs to ensure sufficient deformation space for the elastomer; it must not be compressed solid.

Dynamic Balancing: For high-speed applications (typically >1500 rpm), the coupling should be dynamically balanced. Uneven mass distribution of the elastomer can be a source of excitation.

6. Conclusion and Outlook

The steel curved jaw elastic coupling is a "gem" in industrial drive design. With its ingenious structure, exceptional comprehensive performance, and high economy, it has secured an unshakable market position. The key to its success lies in a profound understanding of the importance of the principle of "adequacy" in engineering practice – providing performance sufficient for the vast majority of industrial applications at a reasonable cost.

For the drive system engineer, the key to correctly applying this coupling type is: First, a clear understanding of its capability boundaries, particularly the critical impact of temperature, speed, and misalignment on elastomer life. Second, treating it as a "system" requiring periodic maintenance rather than a permanent component, and establishing a condition-based maintenance plan.

Looking forward, advancements in material science will continuously yield new elastomer materials with higher temperature resistance, better creep resistance, and tunable damping characteristics (e.g., high-performance TPU composites). These will further expand the application boundaries of jaw couplings, particularly their performance in high-dynamic servo applications and under harsh operating conditions, ensuring they continue to safeguard the reliability and efficiency of industrial drives.