Cautions

1. There are four kinds of elastomers with different hardness in this series, The allowable torque and absorption deviation ofelastomers with different hardness are different, Please pay attention to the selection.

2. Be sure to observe allowable tolerances of eccentricity, deflection and axis.

Bolts must be tightened with specified torque.

3. The scope of use is shownlin the following table of elastomer paramelers, Elastomers have water and oil resistance, but theenvironment of extreme adhesion can also lead to deterioration of products, please avoid such situations.

4. Do not tighten clamping bolts or pressure bolts before inserting them into theihstallation shaft.

Installation

1. Confirm whether the clamping bolt of the coupling is loose or not, remove rust, dust and oil on the inner surface of theshaft and coupling, specially, all kinds of grease that have significant influence on the friction coeticient of the couplingmust not be adhered. Clean the shaft and hole before installation.

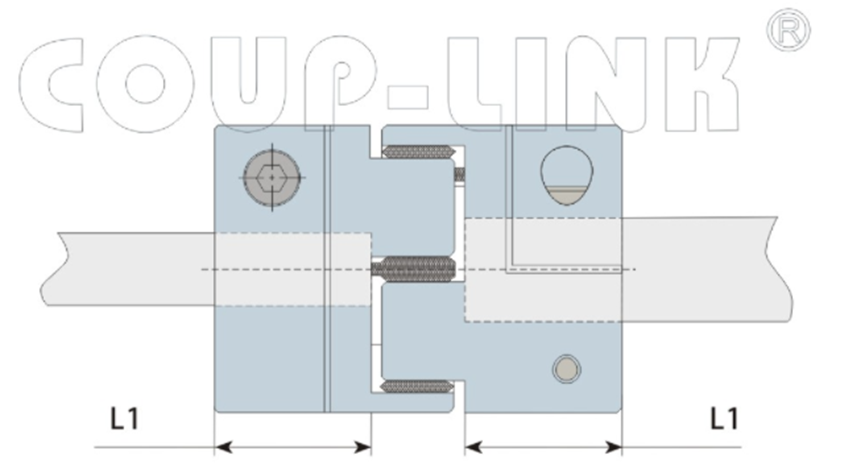

2. Please insert the coupling into the motor shalt, The insertion length must be close to the side section length of the coupling,so that the clamping end has a large enough contact surface with the shaft to ensure sufficient friction.

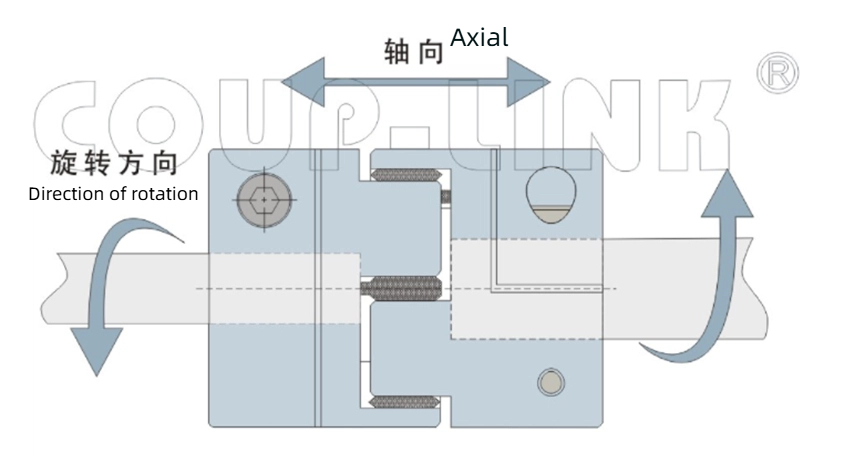

3. When the clamping bolts are loose, make sure that the coupling can move slightly along the axis and rotationdirection, lf it can not move smoothly, please readjust the centering of the two axes, This method is recommendedas a simple method to confirm the left and right concentricity, lf the same method cannot be used, please use othermeasuring methods to confirm the installation accuracy.

4. After confirming that the coupling can move smoothly along the axis and rotatibn direction, tighten the two clampingbolts. When tightening the bolt, please use the calibrated torsion plate hand to tighten the bolt according to theclamping bolt tightening torque listed in the parameter table.

5. As an initial anti-loosening measure of clamping bolt, it is suggested that after running for a period of time, the correcttightening torque should be used again for tightening.